QUALITY

At Rythme Alloys, quality is not just a commitment—it is the foundation of everything we deliver. we ensure every material meets the highest industry standards and customer expectations.

Our operations are driven by precision, advanced processes, and strict quality control protocols. Each product undergoes intensive inspection and testing to guarantee durability, reliability, and superior performance in demanding applications across industries.

INSPECTION FACILITIES

We maintain stringent quality parameters through modern technology, experienced quality personnel, and internationally benchmarked procedures, including:

Metallography & Mechanical Testing

Impact & Corrosion Testing

Radiation Contamination Check

Magnetic Particle (MPT), Ultrasonic (UT) & Liquid Penetrant Testing (LPT)

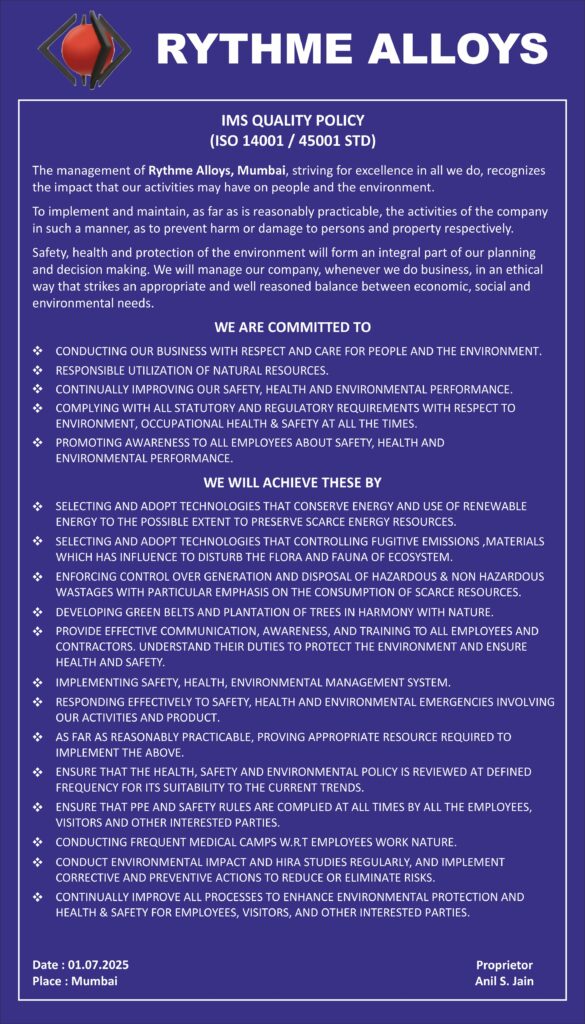

SAFETY

Safety is an integral part of our operations and workplace culture. We are committed to maintaining a safe, healthy, and compliant environment across all processes involved in the handling, storage, inspection, and supply of Stainless Steel, Carbon Steel, and Alloy Steel products.

We follow strict safety protocols and industry best practices to minimize risks and ensure the well-being of our workforce, partners, and customers. Our safety measures include:

Compliance with statutory and industry safety standards

Proper handling, storage, and transportation of materials

Use of personal protective equipment (PPE)

Regular safety training and awareness programs

Continuous monitoring and risk assessment

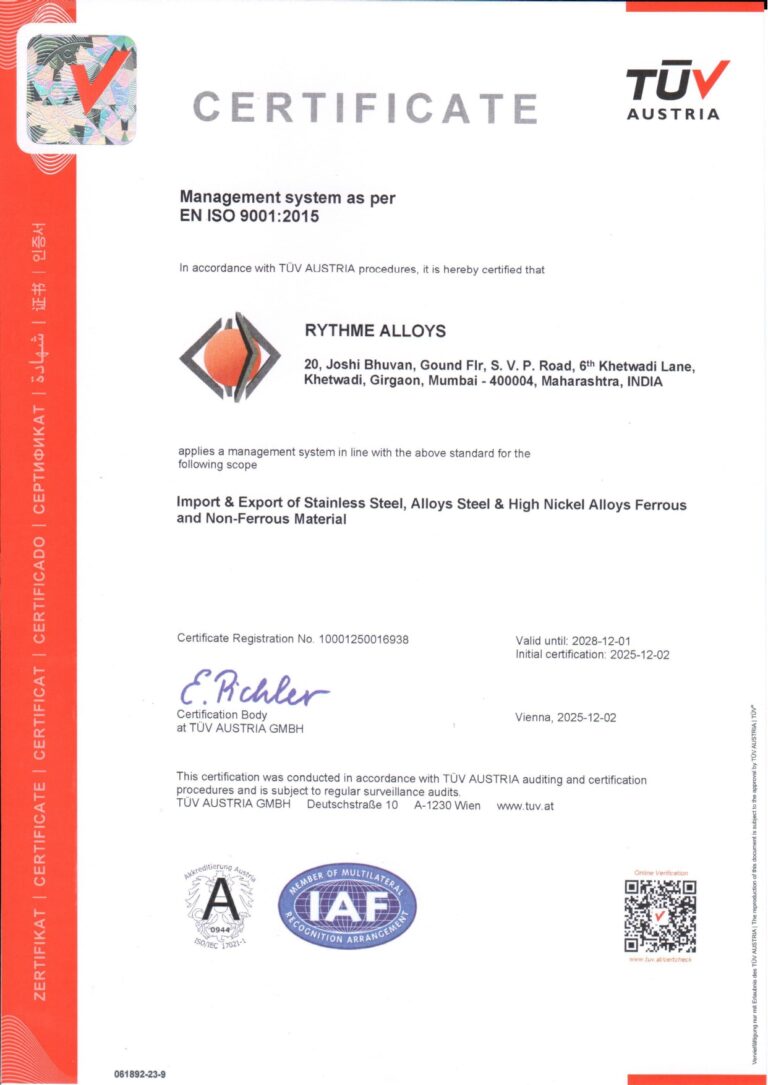

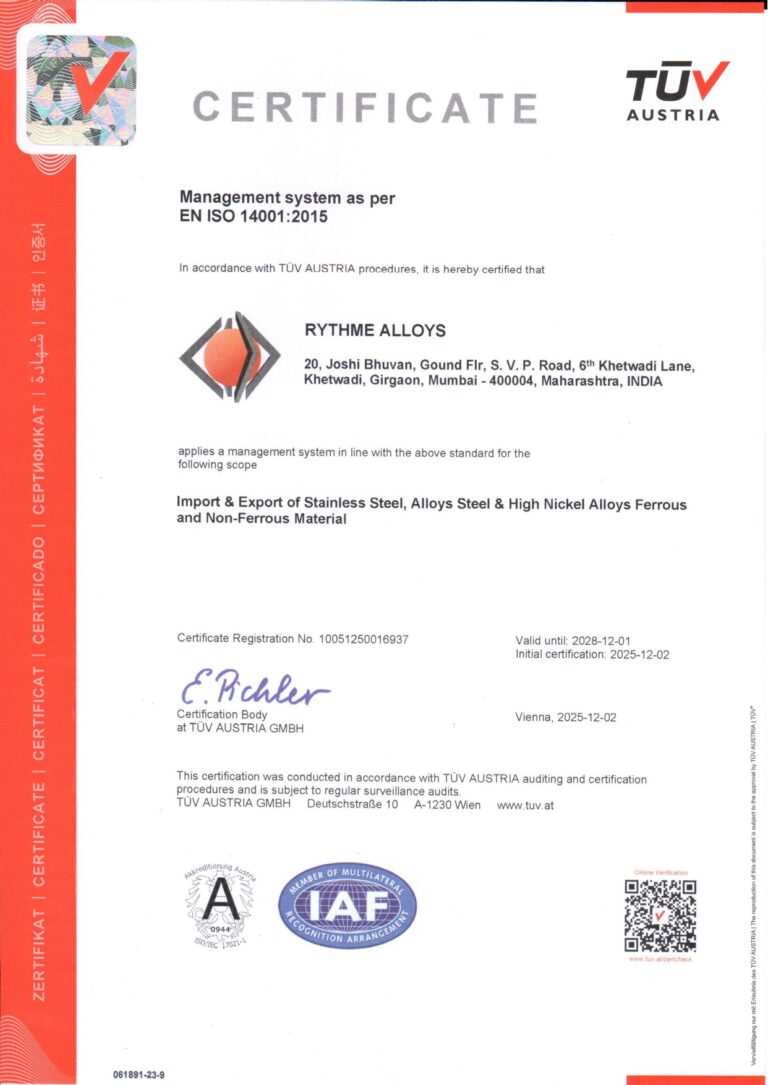

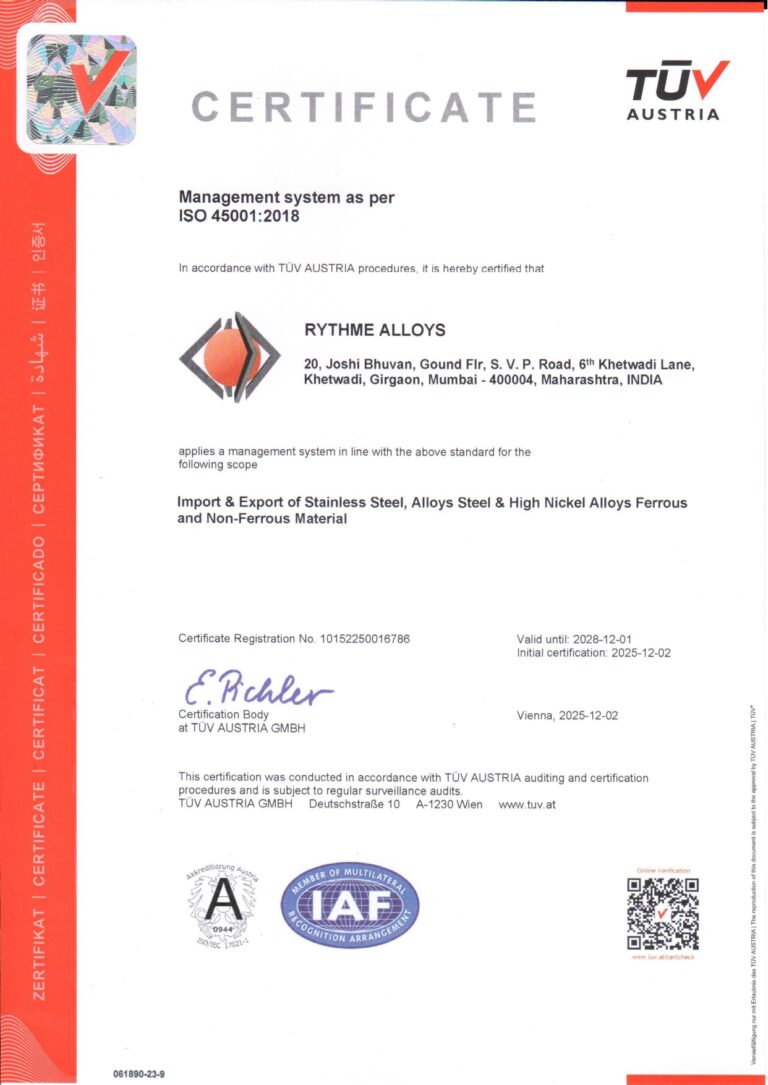

CERTIFICATIONS